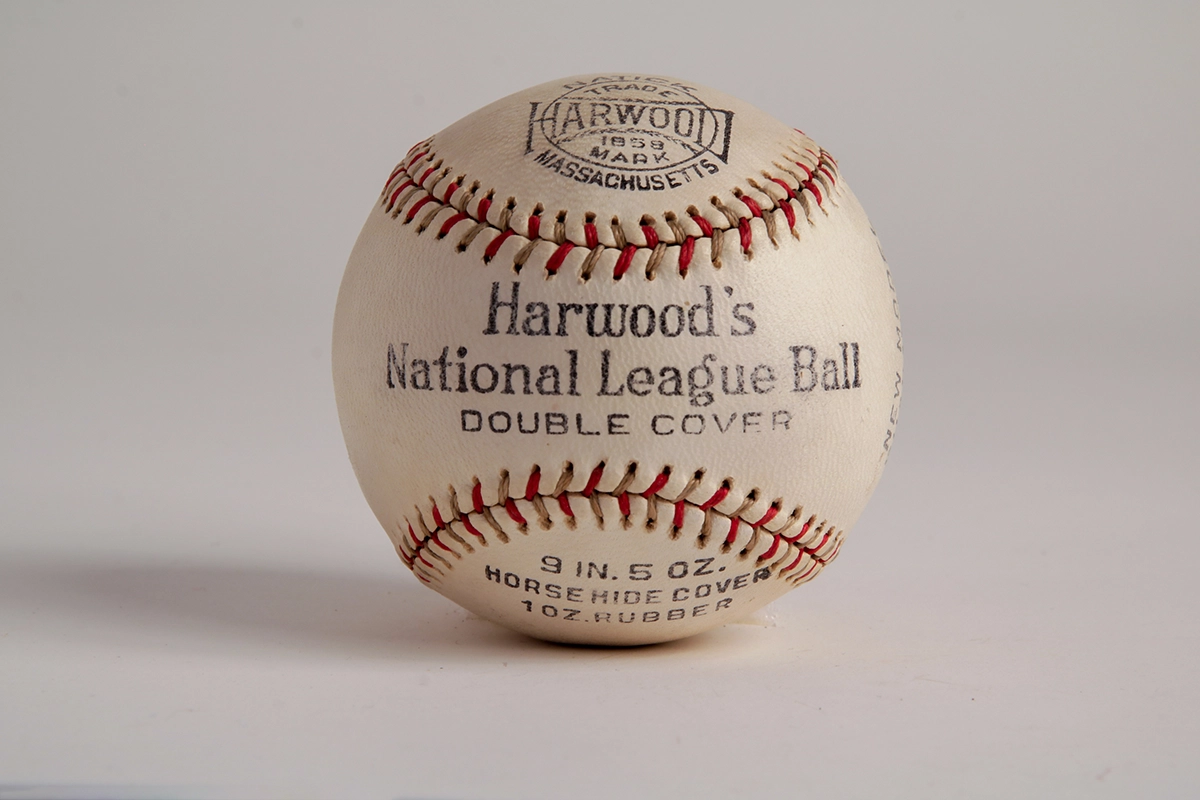

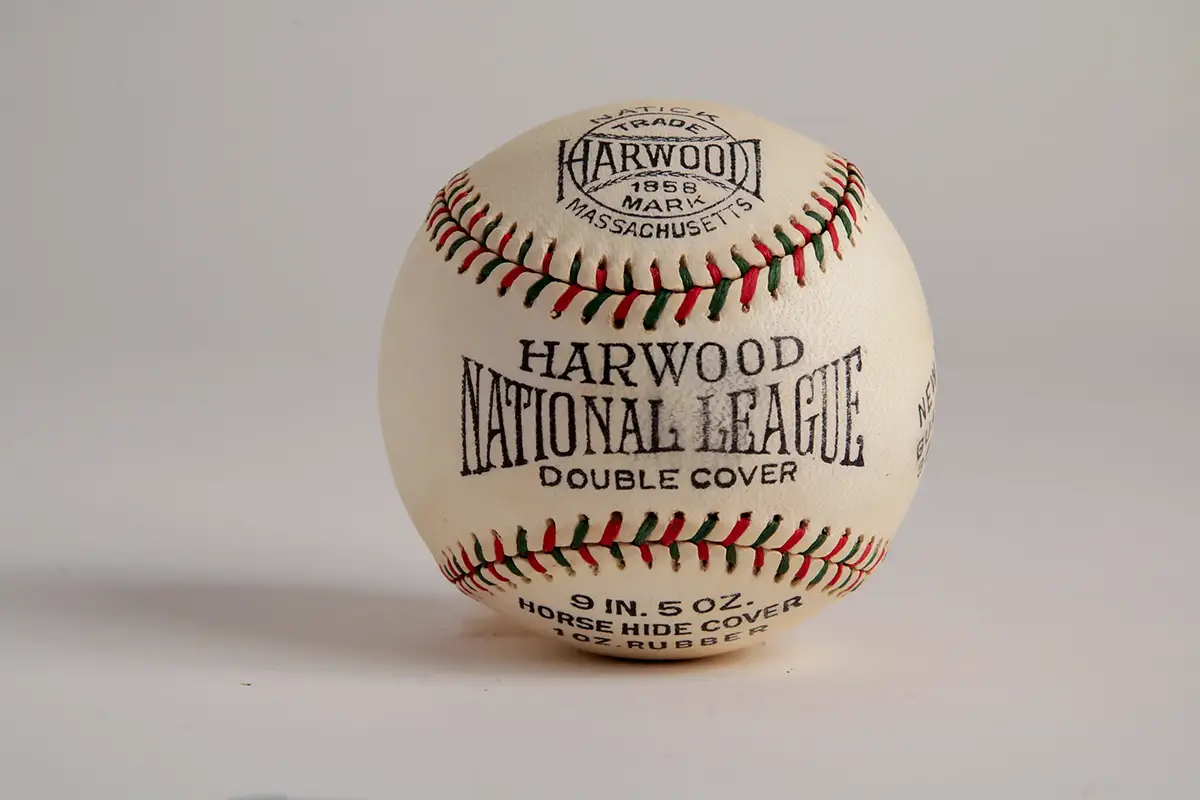

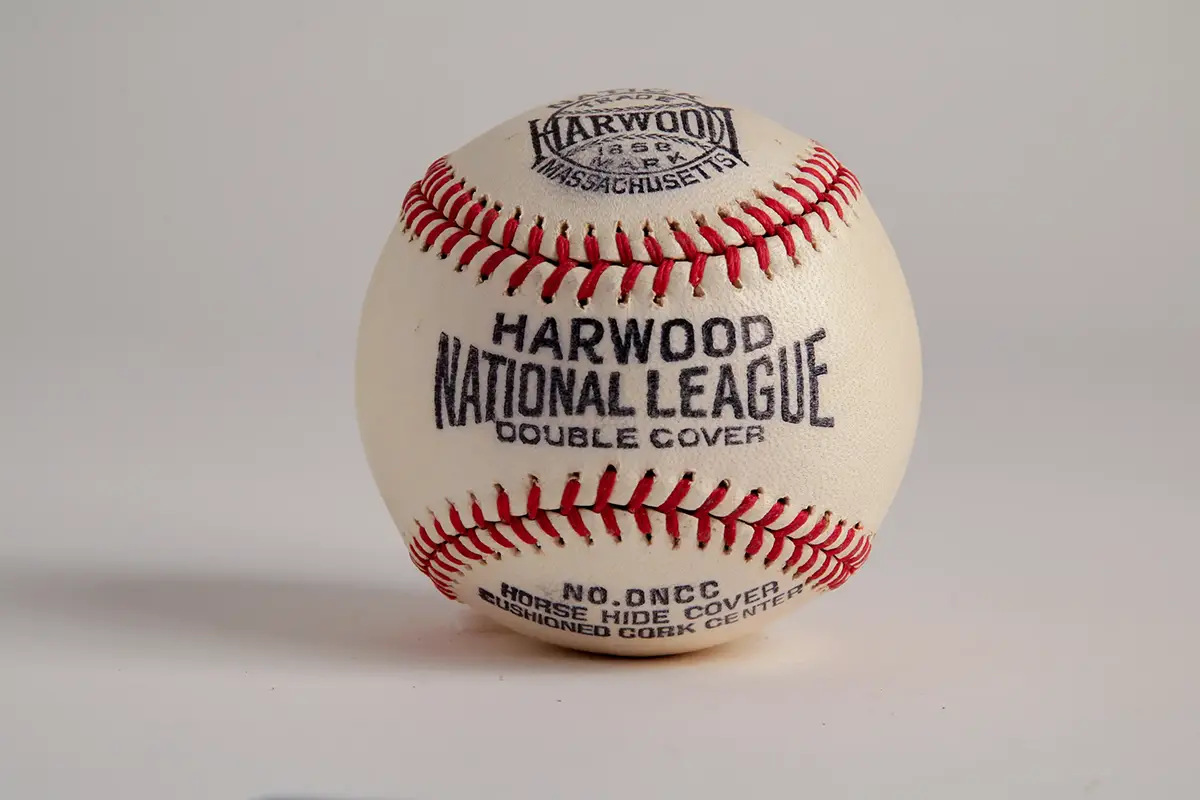

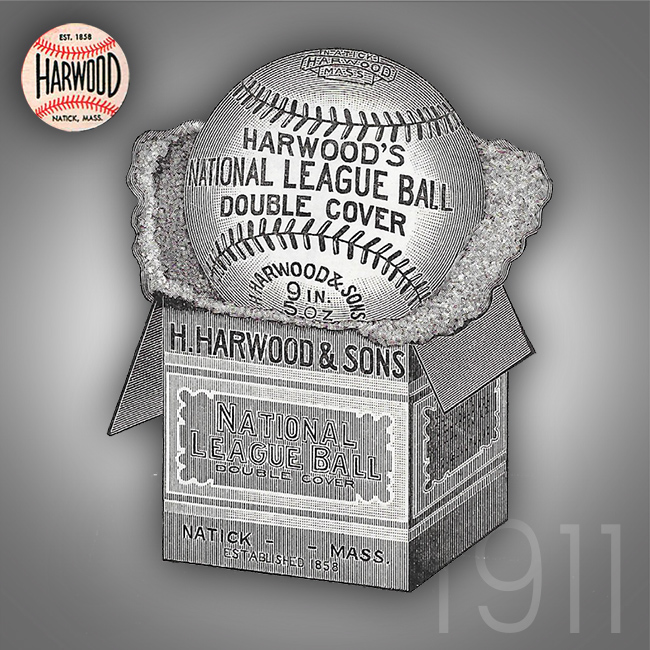

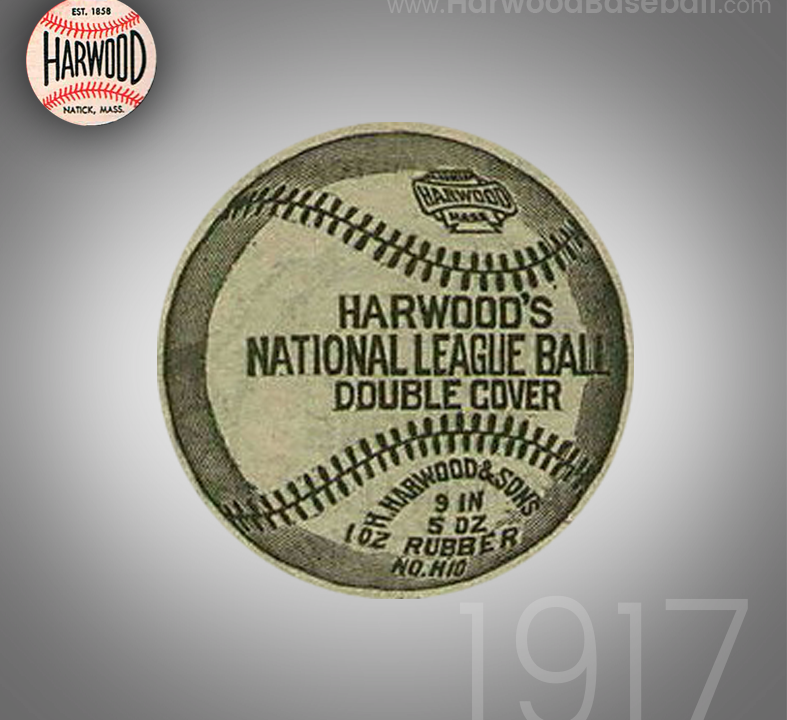

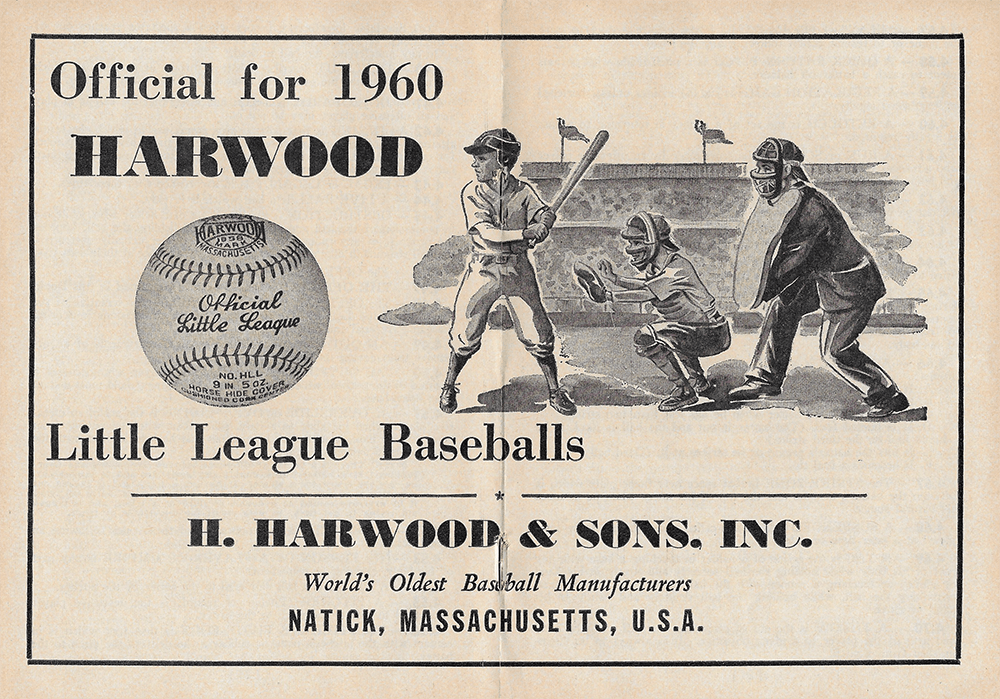

The Harwood & Sons baseball factory of Natick Massachusetts was the first baseball manufacturing facilities in the USA. This location started making the Harwood Baseballs in 1858... Before Spalding and Reach.

Harwood Baseball and this website have no connections or relationships to the Harwood Surname or relations with the Harwood & Sons Baseball Factory.

What do all those labels mean?

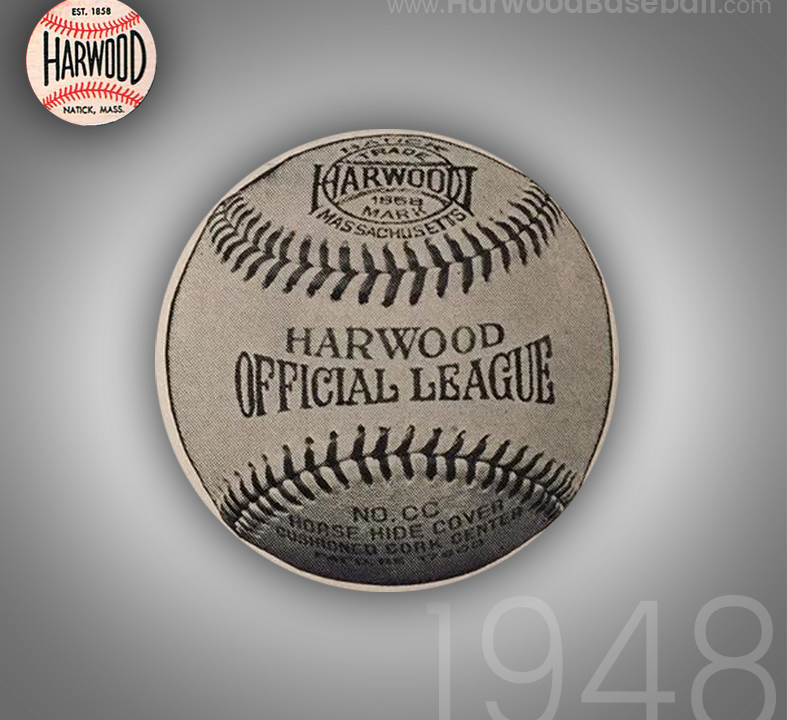

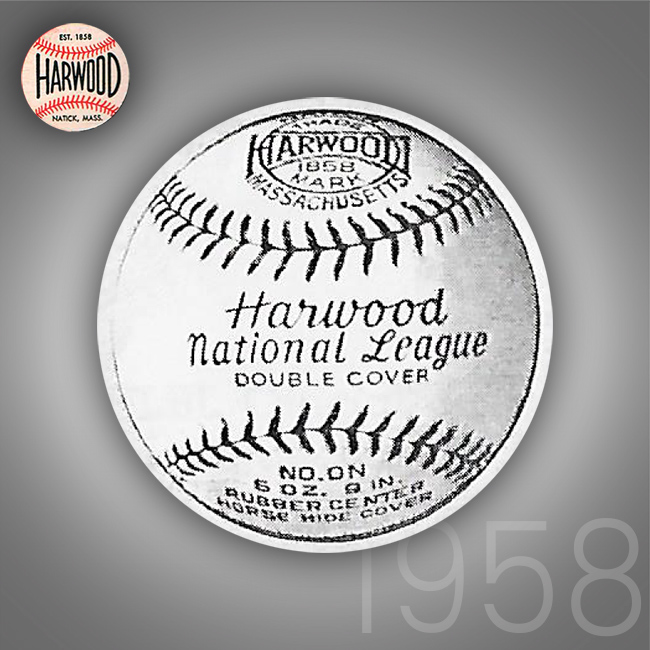

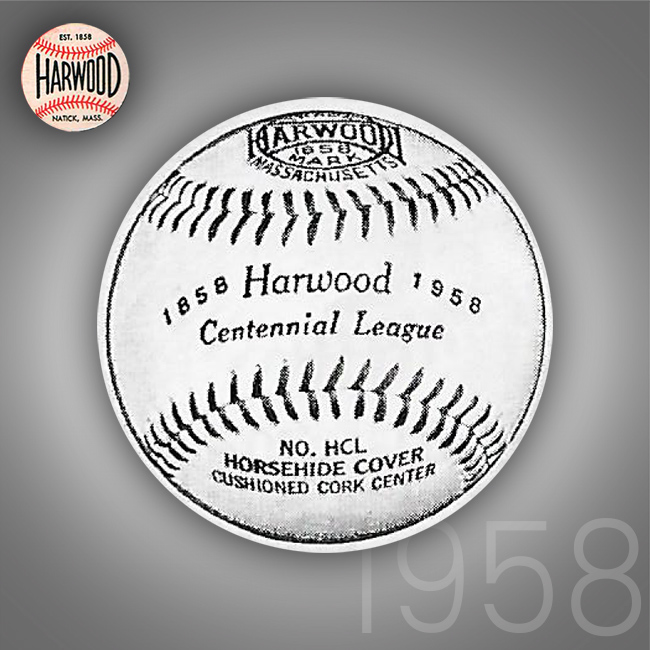

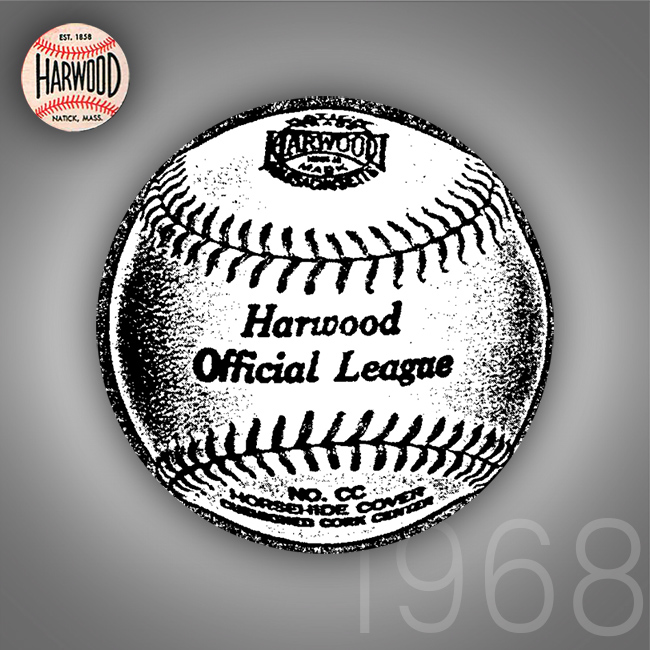

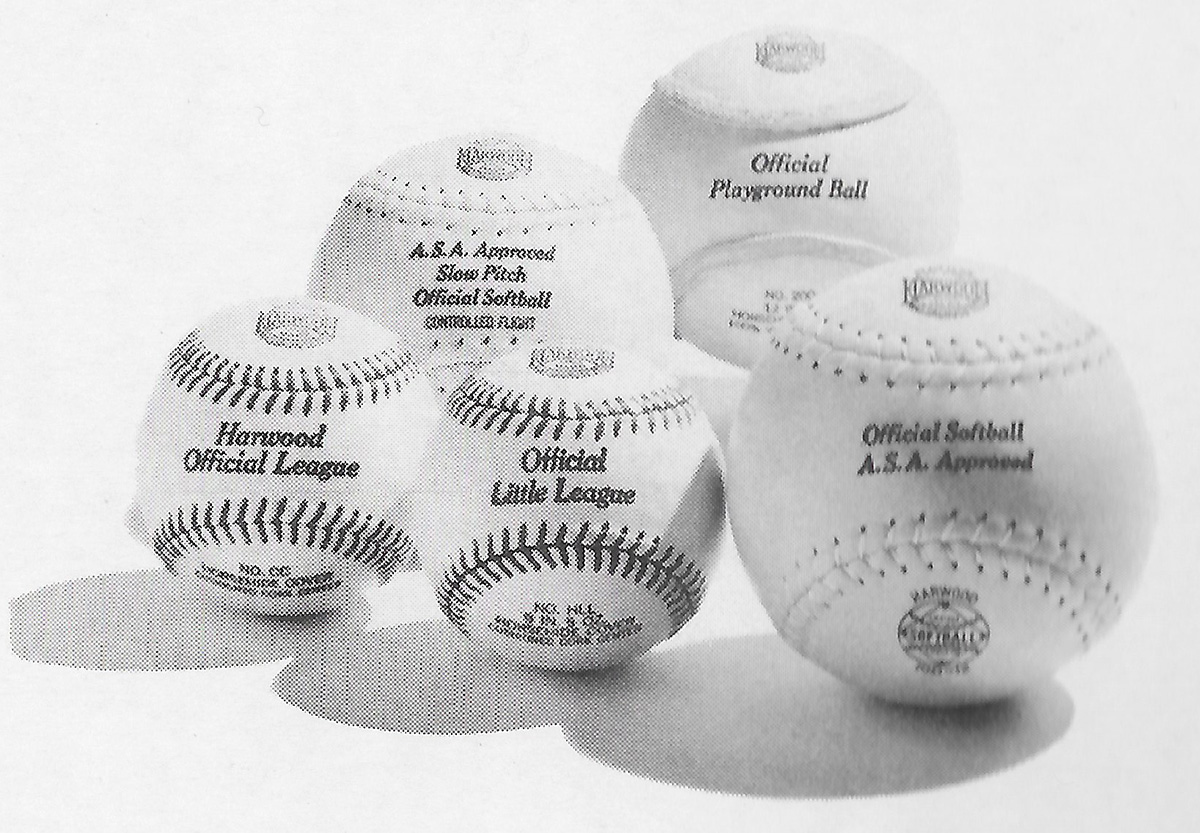

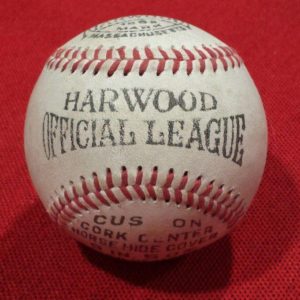

Below is a list of Harwood labels from 1958. These labels were used to identify the different type of baseball which they produced and sold.

Official Harwood Baseball Labels

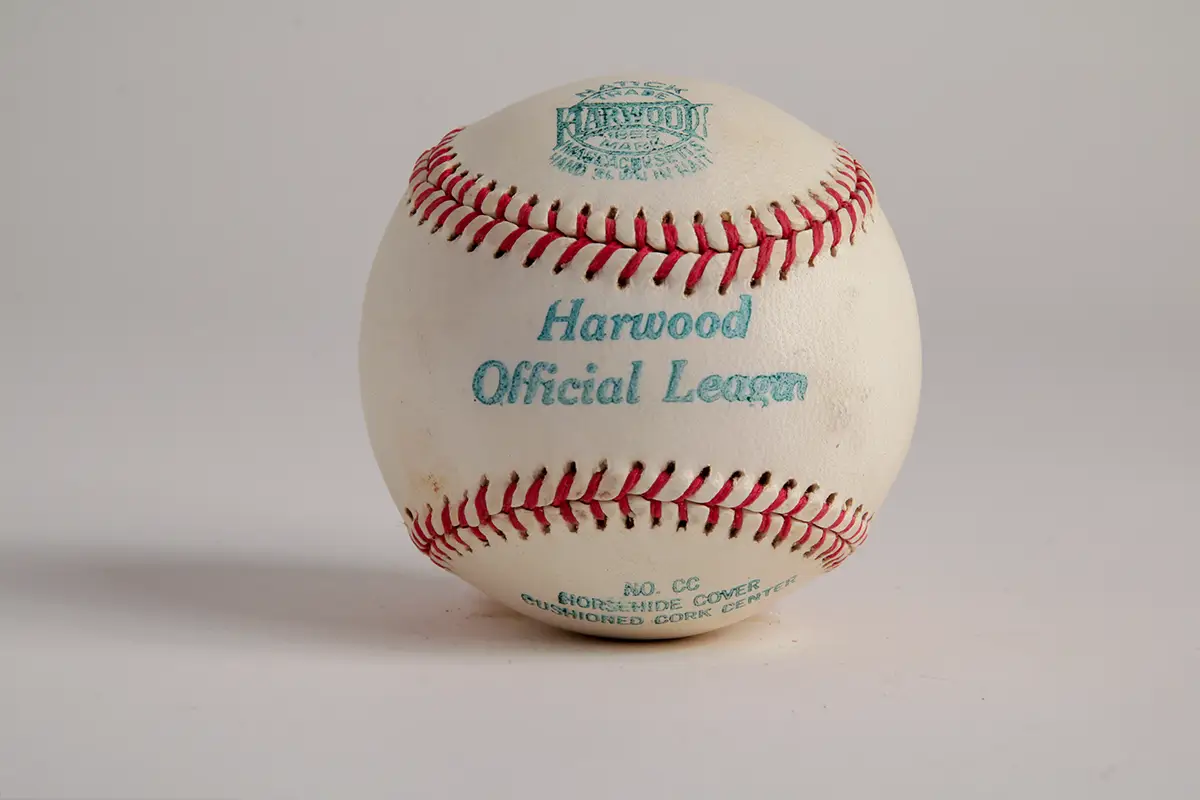

No. CC

Cushioned Cork

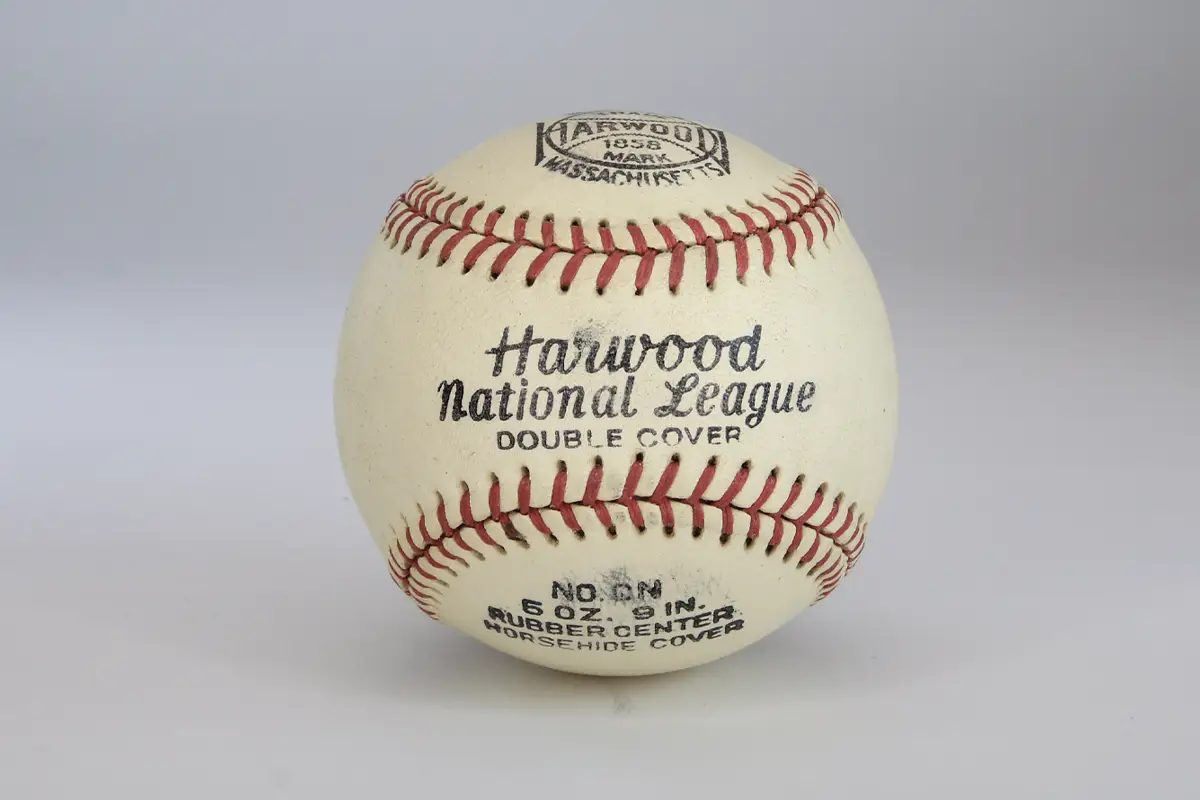

No. ON

Original National League Ball

No. ON-C

Original National League with Cushioned Cork Center

No. ML

Major League

No. AAA

AAA League Specifications. All Wool Yarn for Semi Pro and College Play

Harwood Little League Baseball Labels

No. HLL

Official Little League

No. LLA

Approved Little League

No. LLS

Little League Senior

No. HLBL

Babe Ruth League Play

No. HPL

Pony League

No. HCL

Colt League

No. LBL

Dixie Boys Play

No. LBL

Dixie Youth Play

Misc. Harwood Baseball Labels

No. 1X

Practice Ball

No. 58

Cushioned Cork center wool yarn wound for college and high school play.

No. 90

Extra durable molded cork and rubber center. Horsehide cover

No. 94

Official size and weight for High School and Intermediate League Play. Moderately Priced.

No. 100-SN

Tuff Hide

Ironically...

We have found Harwood Official League balls with a label of No. AA. We are assuming these means AA Minor League Baseball but to this day we do not have proof.

What is in the core of a baseball?

Cork - Rubber - Stone - Marble

Baseball Cores

1800's

Rubber cores were made from melted shoes, wrapped in yarn and leather.

1840s, players crafted homemade hardballs by wrapping small objects; rocks, walnuts and even fish eyes. They would wrap these with yarn before stitching a piece of leather around the orbs.

National Association of Base Ball Players adopted rules in 1858 that required baseballs to have rubber cores covered with yarn and leather. Weight, size and rubber percentage however, were not governed allowing home teams to tailor them to the strengths of their teams.

1840s, players crafted homemade hardballs by wrapping small objects; rocks, walnuts and even fish eyes. They would wrap these with yarn before stitching a piece of leather around the orbs.

National Association of Base Ball Players adopted rules in 1858 that required baseballs to have rubber cores covered with yarn and leather. Weight, size and rubber percentage however, were not governed allowing home teams to tailor them to the strengths of their teams.

1901-1910

1901 to 1910 Major League Baseball used a Rubber Core Baseball.

Rubber remained the primary core of the baseball until 1910 when the A.J. Reach & Company began production of a ball with a center of cork encased in a layer of vulcanized rubber that was patented the year before by Ben Shibe, owner of the Philadelphia Athletics.

This was the beginning of the Dead Ball era (1901-1919). During the fall classic of 1910 a baseball with a center cork was introduced.

Rubber remained the primary core of the baseball until 1910 when the A.J. Reach & Company began production of a ball with a center of cork encased in a layer of vulcanized rubber that was patented the year before by Ben Shibe, owner of the Philadelphia Athletics.

This was the beginning of the Dead Ball era (1901-1919). During the fall classic of 1910 a baseball with a center cork was introduced.

1910-

During the fall classic of 1910 a baseball with a center cork was introduced. The American and National Leagues both adopted the cork-centered ball in 1911.

1922

Cushioned Cork

1931

Introduction of a Cushioned Cork Center.

1934

The National League and American League agreed to standardized the baseball. A cushion cork center; two wrappings of yarn; a special rubber cement coating; two more wrappings of yarn; and a horsehide cover.

1943

Natural rubber shell with less-elastic balata center core.

Japanese cut off rubber supplies at the onset of World War II. Four days after the 1941 bombing of Pearl Harbor, the United States banned the use of crude rubber in any items deemed non-essential to the war effort—including baseballs. The 1943 season was forced to replace the core’s natural rubber shell with less-elastic balata, the same substance used to make the hard outer shell of golf balls.

Japanese cut off rubber supplies at the onset of World War II. Four days after the 1941 bombing of Pearl Harbor, the United States banned the use of crude rubber in any items deemed non-essential to the war effort—including baseballs. The 1943 season was forced to replace the core’s natural rubber shell with less-elastic balata, the same substance used to make the hard outer shell of golf balls.

1944

Spalding introduced the Synthetic rubber core.

1946

Wartime restriction were uplifted and crude rubber returned to baseballs once again.

Baseball Leagues

When was the National League founded?

The National League was founded in 1876

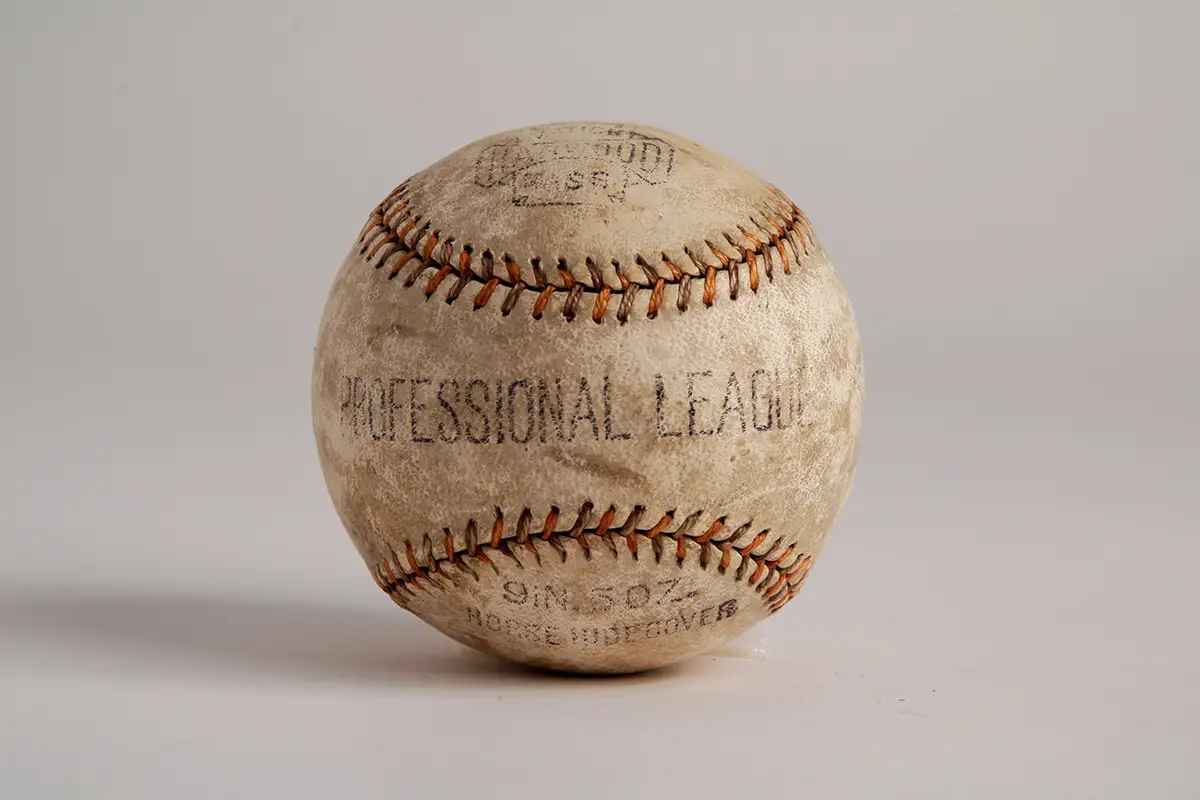

Reach Baseballs

1901-1909

The word "Rubber" is stamped at the bottom panel.

1911-1912

Cork Center

1925

17,200

March 17, 1925 Patent No. 1,530,410 issued. Patent filed September 3, 1924.

March 17, 1925 Patent No. 1,530,410 issued. Patent filed September 3, 1924.

1927

Cushioned Cork

1929

Patent Reissued "Re 17200"